Check Out For These Features In A Forging Parts Manufacturer

Are you looking for forging parts? Well, there are several factors that you need to consider, and among the most important ones is the manufacturer. You need a reliable manufacturer, one that you can trust to deliver your expectations. However, this can be tricky if you do not know what to look for to identify a good forging parts manufacturer. Below, we have listed some of the features to help you get a reliable forging parts manufacturer.

Location

This is one of the factors you need to consider in forging parts manufacturers. Location is one thing you need to check out before anything else. Where is the manufacturer located? Are they located in your region? These are some of the questions you need to ask yourself when choosing a manufacturer. It is important to deal with a manufacturer based in your locality due to quick delivery and cheaper cost of delivery.

Extended experience

The other thing you need to look for in forging parts manufacturers is their level of experience. The kind of experience the manufacturer has gained in the industry explains their product quality. A good manufacturer ought to have been in the industry for a long to improve quality. Therefore the longer time, the better.

A good reputation

Another factor to consider in forging parts manufacturers is the kind of reputation they have in the market. But how do you tell of their reputation? To achieve this, ask around and mainly target previous customers. Know their comments about the manufacturer. Positive comments mean the manufacturer has a good reputation.

Quality material

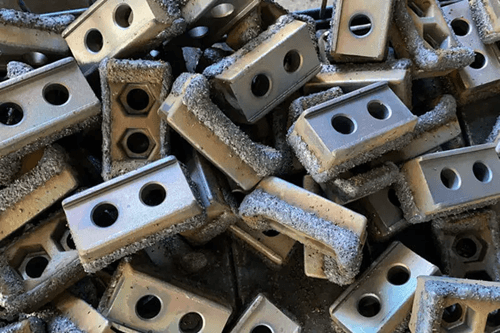

The other factor to look for in forging parts manufacturers is the quality of the materials used in the production. Materials used greatly determines the quality of forging parts offered. Ensure the material used are of high quality to deliver the best parts. A good forging parts manufacturer uses materials of high grades.

Quality technicians

Another thing you need to consider is the quality of the technicians running the forging parts factory. If the factory is under inexperienced technicians, this will highly affect the quality of forging parts. Therefore, a reliable manufacturer should have well-skilled technicians to offer the best products.