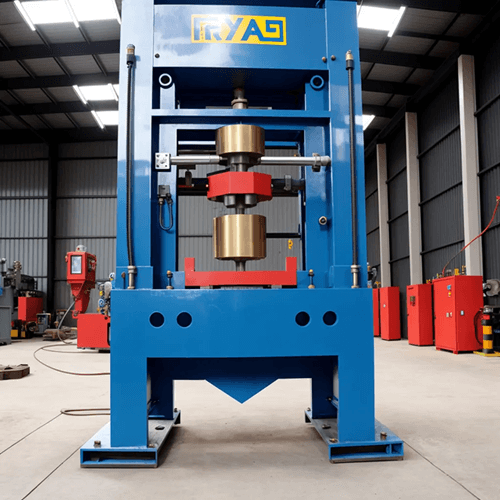

The world of manufacturing and industry relies heavily on machinery that can handle enormous pressure. A 50 ton hydraulic press, designed to exert a force of 50 tons using hydraulic fluid to generate pressure, stands as a testament to this need. With its capability to transform metals, plastics, and other materials with ease, a hydraulic press is an indispensable tool. Let’s explore 5 of its major uses:

-

Metal Forming & Stamping

Metal forming is one of the most common applications for hydraulic presses. Manufacturers use the press to shape and mold metal sheets into desired forms. Through processes like deep drawing, coining, and blanking, industries can produce car body parts, kitchen utensils, and countless other metal products. The 50 ton hydraulic press offers the perfect balance of power and precision for such tasks.

-

Compression Molding

In the realm of plastics, a hydraulic press plays a pivotal role in compression molding. This method is particularly prevalent in the production of thermosetting plastics. The process involves placing a preheated plastic material in an open, heated mold cavity. The mold is then closed with the hydraulic press, applying pressure to force the material to conform to the shape of the mold.

Forging and Cold Forging

Forging involves heating a metal piece and then using the hydraulic press to shape it. Cold forging, on the other hand, is done at or near room temperature. The 50-ton hydraulic press can be employed in both processes, and it’s particularly beneficial for producing smaller parts with detailed features.

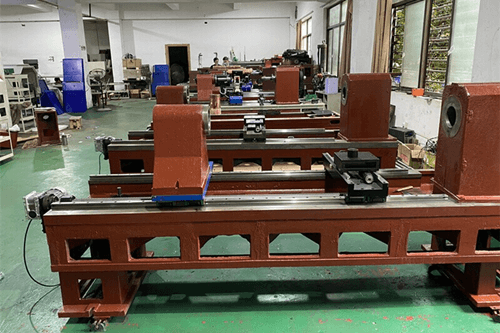

Laminating

Laminating is the process of bonding multiple layers of materials together. With the aid of a 50-ton hydraulic press, layers can be firmly adhered, ensuring a secure bond. This technique is commonly used in creating multi-layered circuit boards, protective coverings, and decorative surfaces for furniture and countertops.

Extraction and Testing

In research and lab settings, hydraulic presses are frequently employed for extraction processes. For example, extracting juices or oils from plants and fruits under high pressure to ensure maximum yield.

Check out https://www.blyhydraulicpress.com/ for some of the best quality and affordable 50 ton hydraulic press machines and a range of other press sizes.