If you have just purchased an electric hydraulic press or planning to buy one, there are several things you need to get right. Unlike the typical manual machines, these machines are a bit complex though to work with.

The electric hydraulic press uses a motor to produce the required force. The motor rotation develops movements on the hydraulic system to replace manual exertion. Therefore, they have some level of automation in the process of developing the compression force.

There are several things that you need to get right to work with an electric hydraulic press. In this blog, we are going to look at some of the things that you need to consider. Check out the following:

Availability of Power

The first thing that you need to get right is the availability of power. This is an important factor to consider because you will not use the machine without power and the right power source. What kind of power is the machine using? Is it a single phase, or it is a large machine that is using 3-phase power? You need to have the right power for the machine. You also need to ensure that you have a constant power supply in your area if you want to use these machines properly.

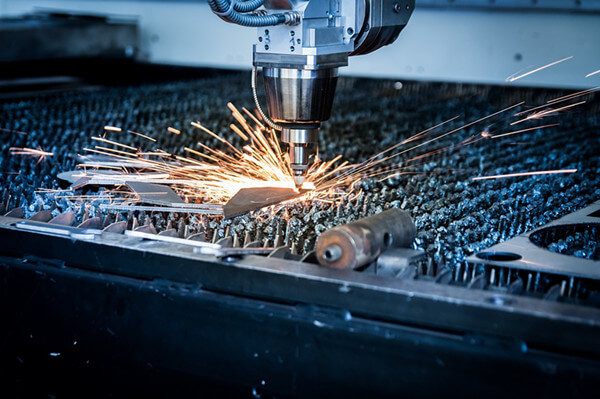

Safety Measures

The other thing that you need to get right to use an electric hydraulic press is safety. With this level of automation and the inclusion of motors, it means the risk of injuries is also high. You need to have all the safety protocols well-understood and observed if you are to work with the machine. Make sure that you have reduced or removed that are likely to cause accidents. Ensure that the areas around the machine have been cleaned thoroughly to remove anything that increases the risk for operators.

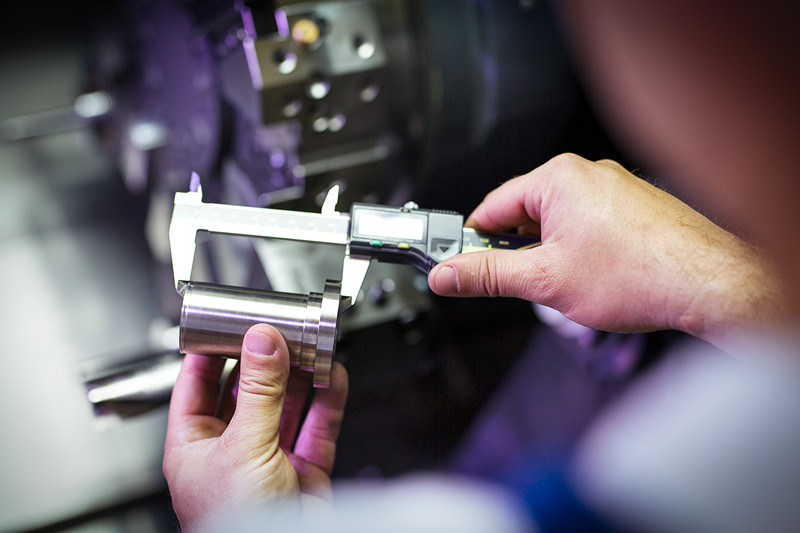

Trained Operator

The other thing that you need to get right to work with an electric hydraulic press is the operator. Because of the inclusion of the electrical devices, then the operation of the machine is deemed more complex. You need to ensure that you have the best operator for the job. Make sure they have been trained and have experience in operating the electric hydraulic press you will be using.

These are the three major things you need to consider for the proper use of the electric hydraulic press. Without them, you will have a lot of difficulties dealing with these machines.