The availability of FAE teeth is not an issue, especially if you are not interested in buying the original manufacturer’s parts. There are many other suppliers in the market and one of them is the aftermarket supplier.

These are teeth suppliers who work independently to produce tools that fit your FAE mulcher and other brands. Choosing the right one is the most important thing. There are several things you need to check in aftermarket FAE teeth suppliers and they include:

Good Experience

The kind of experience the aftermarket FAE teeth supplier has is one of the first things you need to consider. Do not make the mistake of buying from a manufacturer that is not experienced enough to provide a machine cutter of the market standards.

Market Reputation

The name that the manufacturer has in the market is another factor to consider. Dealing with a reputable manufacturer guarantees the right tools or the parts you are looking for. For the aftermarket FAE teeth suppliers, you need to work with the most reputable in the market.

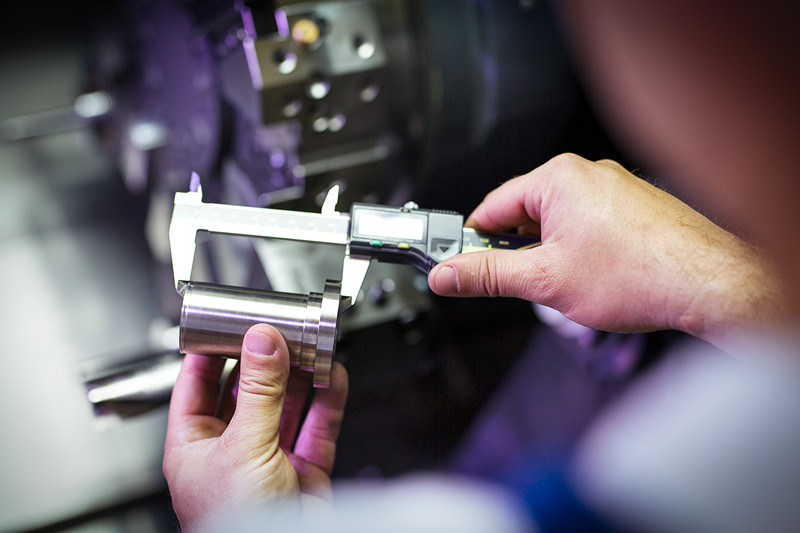

Quality of Parts

Check the quality of FAE teeth that the aftermarket supplier is providing. There are all kinds of qualities in the market you can select from depending on what the machine is being used for. Raw materials used is one fo the crucial factor to consider. You also need to check the quality of the production including heat treatment.

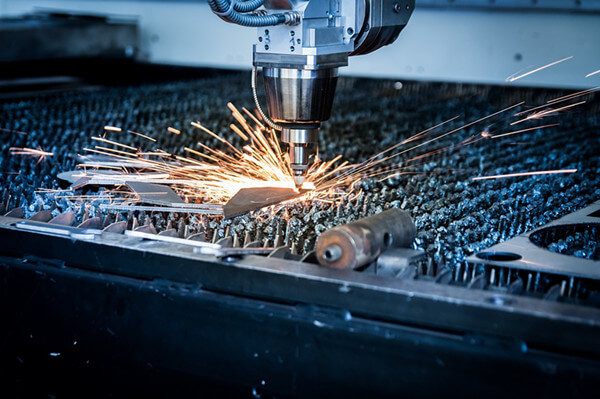

Production Technology

The technology that aftermarket FAE teeth suppliers are using for the production of the machine parts is another factor to consider. You need to ensure that they have the best quality technology the market can offer. This is important because it determines the quality you get.

Prompt Delivery

Check whether the aftermarket FAE teeth supplier is offering prompt delivery. This is crucial, especially if you know that you are likely to be dealing with downtime. You need a supplier that has a reputation of delivering promptly as promised.

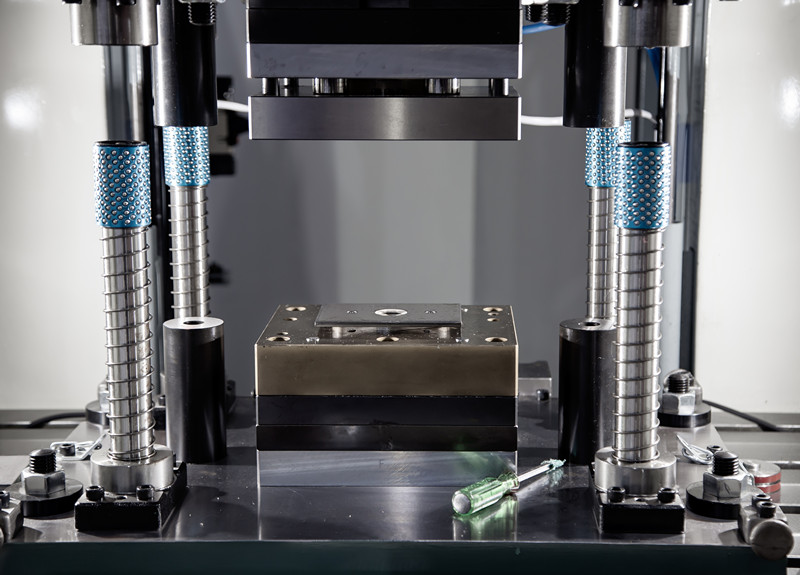

Customized Products

Does the aftermarket FAE teeth supplier has the capability of providing customized products? You need to get this answer because customized machine parts are the way to go. If they can provide customized teeth for your FAE machine, then they are one of the best suppliers to work with.

Affordability

The aftermarket FAE teeth supplier must be affordable. The cost should be equivalent to the quality of the product. Avoid overpriced FAE teeth just because the brand is popular in the market.