Continue reading Benefits of Investing Tungsten Carbide Tub Grinder Tips

Continue reading Benefits of Investing Tungsten Carbide Tub Grinder Tips

Category Archives: BLOG

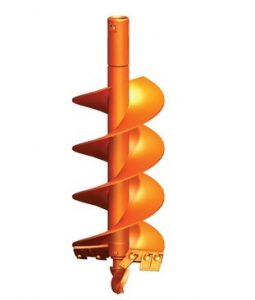

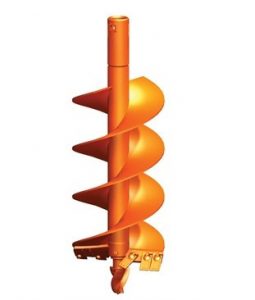

Drilling With Pengo Auger Teeth

Planning To Buy Pengo Auger Teeth? Look For These Features

How Brazing Tungsten Carbide Saves You Money

How Brazing Tungsten Carbide Saves You Money

Brazing tungsten carbide is one of the most sought after techniques in the market. It has quickly replaced the tradition soldering technique in the manufacturing of industrial machine tools. For almost all cutter teeth in the market, they are made from this technique. It is also one of the areas that most manufacturers are marketing their machine cutter tools.

Unlike the soldering technique, brazing tungsten carbide produces powerful joins that can withstand the most demanding conditions. With such string joints, it simply means that you can work with these tools for a long time without breaking. Although tools made from brazing tungsten carbide could be a little bit expensive, they save users a lot of money in the long run. Here are just a few ways that you will be saving money with tungsten carbide brazed cutter tools:

Fewer Repairs

One of the biggest saving that you will be making is in repairs. Compared with the soldered cutter teeth, these tools require fewer repairs in the long run. Note that the joint is too strong to break, and thus you will not have to repair breakages. The other problem that is common with the cutter teeth is bending at the joint hence making it difficult for the machine to work. These are problems that you will rarely experience with brazing tungsten carbide technique. Your tools will be able to maintain their original conditions for long.

Few Replacements

There is no doubt that the largest cost of maintaining the machine is in the replacement of the worn down wear parts. That a common problem with soldered cutter teeth as they are not strong enough to withstand the most demanding conditions. Most of the soldering technique cannot withstand the high heat and pressure produced during the drilling work. That is why the replacement of broken and weak joints is a common thing. But with brazing tungsten carbide technology, that will not be a big problem. You will have very few cases of replacements hence saving you money in the long run.

Longer Useful Life

The other way that you will be able to save money is the longevity of the tools. Due to the strength of the joint, tungsten carbide brazed teeth will last for longer than the soldered ones. That simply means a lot of saving in the long run. The fact that it will take you a long time before you can think of replacing your machine cutter teeth means you will be spending less on the machine.

Common Mistake to Avoid When Buying Auger Bit Replacement Teeth

Common Mistake to Avoid When Buying Auger Bit Replacement Teeth

Buying replacement wear parts is something you have to do now and then if you are in the drilling industry. That is because of the high rate of tools’ wear, especially if you are drilling in tough conditions such as sinking boreholes or foundation drilling. But the trickiest part is selecting the right auger bit replacement teeth while buying. So what should you do? Well, there are some of the common mistakes that buyers make you should avoid. These are mistakes that makes them buy low quality or fake auger bit replacement teeth. Here are the main mistakes that you should always avoid:

Not Doing Thorough Research

One of the common mistakes that people make, especially the first time buyers are not doing adequate research. So they go into the market with the correct information on what to look for in an auger bit replacement teeth. That’s why they are easily confused by rogue traders and are sold fake products at the price of the original products. Therefore, get well informed before going into the market.

Going Cheap

Everyone wants to save money, and that is good and smart. But when it comes to industrial tools, saving might be compromising the quality of tools you are buying. Do not try to go cheap while buying auger bit replacement teeth. If you have a small budget, it would be wise to go for the best option, especially if you are buying original tools. A good choice would be aftermarket auger bit replacement teeth as they are the cheaper than originals and still offers the best quality. But do not compromise quality while trying to save money.

Don’t For Second-Hand Parts

The third mistake that most buyers make is going for second-hand auger bit replacement teeth. It is true that there are short time benefits that come with buying second-hand tools. But they should not be the first option. These tools are sold cheaply, and that is why most users opt for them, especially when they are in good order. But you should always remember that these are parts that have been used on another machine and thus you will be missing a certain percentage of their lifespan. That is why you should not put your money in them if you are looking long term.

These are some of the common mistakes that you should avoid while buying auger bit replacement teeth.